Material

| Material | Aluminum | Steel | Stainless Steel |

| Finish | Polished | Zine Plated | Polished |

Specification

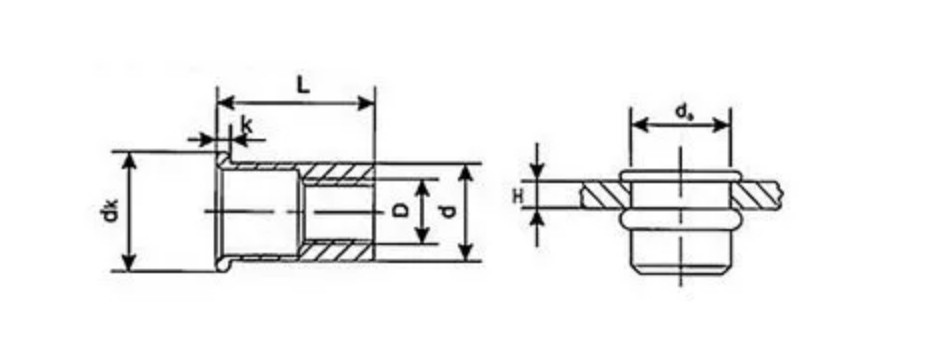

| CODE | Size d |

Grap Range e |

Length h |

D。 +0.15 +0.05 |

D -0.03 -0.2 |

dk +0.30 -0.30 |

K +0.2 -0.20 |

L +0.30 -0.30 |

|

| SM3 | SM3R | M3 | 0.5~2.0 | 5.0 | 5 | 5 | 5.5 | 0.4 | 8.5 |

| SM4 | SM4R | M4 | 0.5~2.0 | 5.5 | 6 | 6 | 6.75 | 0.5 | 10.0 |

| SM5 | SM5R | M5 | 0.5~2.5 | 6.0 | 7 | 7 | 8.0 | 0.6 | 12.0 |

| SM6 | SM6R | M6 | 0.5~3.0 | 9.0 | 9 | 9 | 10.0 | 0.6 | 14.5 |

| SM8 | SM8R | M8 | 0.5~3.5 | 10.0 | 11 | 11 | 12.5 | 0.6 | 16.5 |

| SM10 | SM10R | M10 | 0.5~3.5 | 12.0 | 13 | 13 | 14.5 | 0.85 | 19 |

| SM12 | SM12R | M12 | 0.5~3.5 | 14.5 | 15 | 15 | 16.5 | 0.85 | 22.5 |

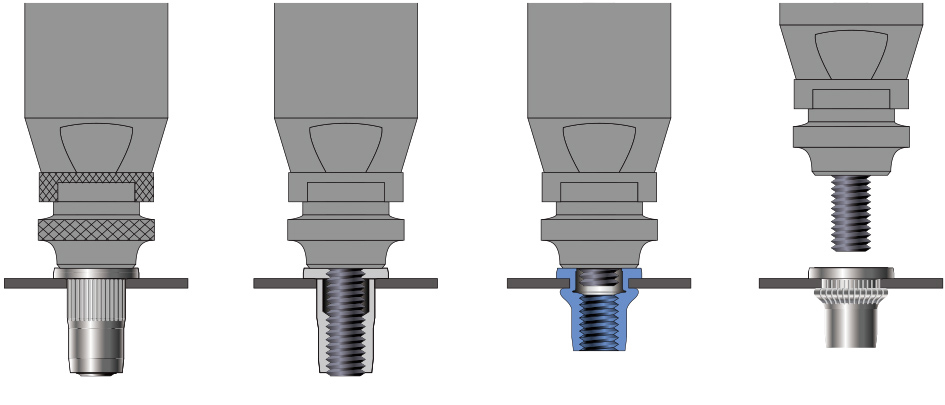

Application

Rivet nut, also known as insert nut, is used in the fastening areas of various types of metal plates, pipes and other manufacturing industries. In order to solve metal thin plates and thin tube welding nuts, the substrate is easy to weld and deforms, and the internal thread is developed. It does not need to attack the internal threads, no welding nuts, high rivet strong efficiency, and convenient use. The rivet nut can effectively solve the air conditioning shell, and can effectively cut the problems such as virtual welding.

The specifications of insert rivet nuts are actually divided into many, such as the standards of rivet nuts used in different types or different sizes of cabinets are different. Some part of the material of the rivet nut is made of carbon steel, and its shape is round. Their thread specifications are between M2 and M10. Most of the outer diameter of this riveting nut pillar is 6.3 mm -17.35 between millimeters. The size and thickness of the riveting thread pillar should be based on the objects to be installed.

Application of rivet nuts in air conditioning:

1. The rivet nut can effectively solve the air conditioning shell, forming the problem of "yellow water" after a long period of time, and can effectively cut the problems such as virtual welding.

2. The rivet nut has replaced the edge attack wire that can reduce the material by 20%and save energy.

3. Solving the edge self -attack screws are not strong, and the reliability can be reduced. It can decrease the noise generated by loosening due to the connection, which can become more reliable, strong, and convenient.

4. Improve production efficiency, reduce the number of workers, and reduce labor costs. (Because the rivet nuts use the method of riveting the crusher of the punch, the single welding method is completed at one time, which not only is efficient, but also reduces the amount of use.

5. Reduce factory ground.