Material

| Material | Aluminum | Steel | Stainless Steel |

| Finish | Polished | Zine Plated | Polished |

Specification

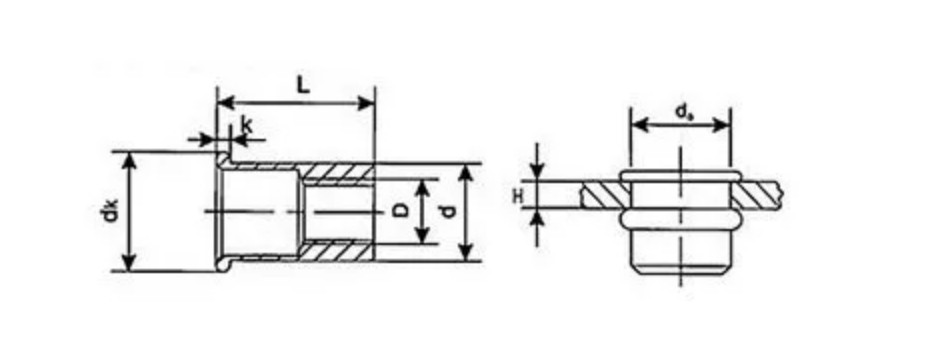

| ODE | Size d |

Grap Range e |

Length h |

M。 +0.15 +0.05 |

M -0.03 -0.2 |

dk +0.3 -0.3 |

K +0.2 -0.2 |

L +0.3 -0.3 |

| FM4h | M4 | 0.5~2.5 | 6.5 | 6 | 6 | 9 | 0.8 | 10.8 |

| FM5h | M5 | 0.5~3.0 | 8.0 | 7 | 7 | 10 | 1.0 | 13.0 |

| FM6h | M6 | 0.5~3.5 | 8.5 | 9 | 9 | 13 | 1.5 | 15.0 |

| FM8h | M8 | 0.5~3.5 | 10.5 | 11 | 11 | 15 | 1.5 | 18.0 |

| FM10h | M10 | 0.5~3.5 | 12.5 | 13 | 13 | 17 | 1.8 | 20.3 |

| FM10h(12) | M10 | 0.5~3.5 | 12.5 | 12 | 12 | 17 | 1.8 | 20.3 |

Application

Rivet nut is a good choice of thin plate connection process. It changes the method of traditional handicrafts. When installing parts on the plate, there is no need to attack the thread or welded nuts. Simple and high efficiency is installed, suitable for thick steel plates, wooden boards, aluminum alloy plates, plastic plates, etc. It is dozens of times that of general bolts, and the most common on sheet metal parts and fashion sports sheet metal parts.

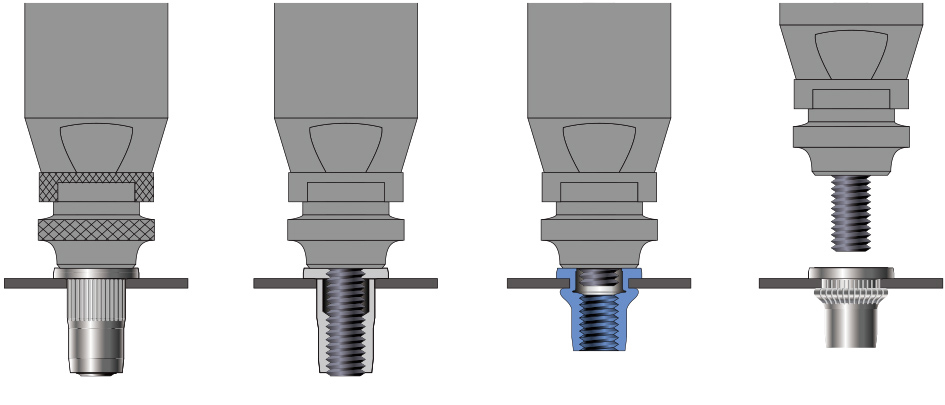

The elements of riveting nut can be divided into three parts:

That is the head can support surface; deformation area can compressed deformation surface; thread area can vertical connection surface.

The three parts together constitute the whole body of the rivet nut, making it have strong mechanical properties.

Main materials for riveting nuts:

The main application is specially used as steel, stainless steel, aluminum, and copper as the main material. The characteristics of different materials are distinguished by mechanical performance, price, corrosion resistance and weight. Choose different materials of rivet nuts.

The main function of rivet nut:

1. The connection of multiple plates is similar to the connection method of rivet nuts. The riveting nut also riven different boards through riveting tools to form a safe and stable connection;

2. Provide threads between the materials at both ends, and the vertical direction of the plate after riveting forms a connected point connection point to provide a thread to provide the thread connection with other parts of the finished product.

3. Different from the rivet, the vertical direction of the rivet nut can be removed, and the rivet does not have the connection point of the vertical direction connection, and the non -demolition is available.

Mechanical performance evaluation method:

The maximum yield -that is, the bite force of the connection formed by the rivet nut, which is also the fixed force of the fixed board;

Maximum torque -that is, the maximum torque that can bear the internal thread of the rivet nut.

The performance of these two parts is an important parameter for choosing a rivet nut. It is usually the basis for us to judge what the customer needs.