Material

| Body | Aluminum ( 5052) | Steel | Stainless Steel ● | |

| Finish | Polished | Zinc Plated | Polished | |

| Mandrel | Steel | Stainless Steel | Steel | Stainless Steel ● |

| Finish | Zinc Plated | Polished | Zinc Plated | Polished |

| Head Type | Dome, CSK, Large Flange | |||

Specification

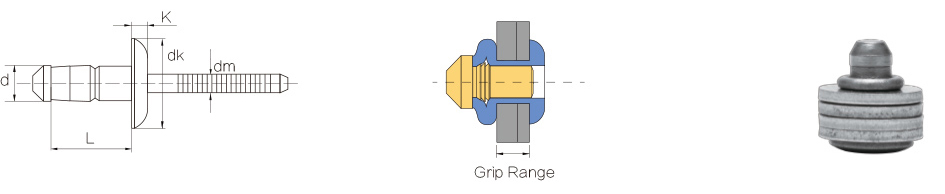

| Size | Drill | Part No. | M | Grip range | B | K | E | Shear | Tensile |

| max | max | max | max | KN | KN | ||||

| 3.2 (1/8") |

|

BBP61-0408 | 8.9 | 1.0-3.0 | 6.6 | 1.1 | 2.1 | 1.6 | 2.0 |

| BBP61-0411 | 11.4 | 3.0-5.0 | 6.6 | 1.1 | 2.1 | 1.7 | 2.0 | ||

| BBP61-0414 | 13.6 | 5.0-7.0 | 6.6 | 1.1 | 2.1 | 3.2 | 2.0 | ||

| 4.0 (5/32") |

|

BBP61-0509 | 10.1 | 1.0-3.0 | 8.0 | 1.5 | 2.6 | 5.2 | 4.0 |

| SSP01-0512 | 12.5 | 3.0-5.0 | 8.0 | 1.5 | 2.6 | 5.2 | 4.0 | ||

| BBP61-0516 | 15.1 | 5.0-7.0 | 8.0 | 1.5 | 2.6 | 5.2 | |||

| 4.8 (3/16") |

|

BBP61-0611 | 12.9 | 1.5-3.5 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 |

| BBP61-0614 | 15.5 | 3.5-6.0 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 | ||

| BBP61-0618 | 18.5 | 6.0-8.5 | 9.6 | 1.5 | 3.1 | 5.5 | 5.0 |

Application

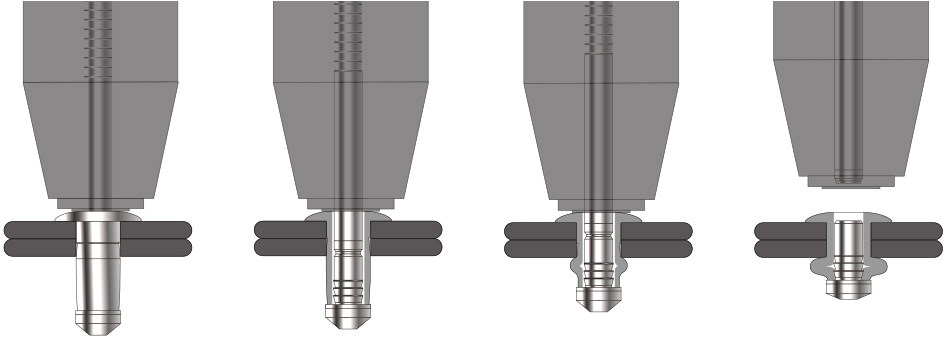

Uni-Grip type blind rivets are structural type blind rivets. Uni grip type blind rivets pull rivet rifles into single -drum types when riveting rivets, clamp the two structural parts to be riveted, and reduce the pressure on the surface of the structural part. It is suitable for high intensity riveting. Thin structured parts. It has a certain protective effect on riveting parts to avoid deformation of riveting holes and destroying riveting parts.

The main purpose of general Uni grip type blind rivets is for vehicles, ships, buildings, machinery, electrical, aircraft, containers, elevators and other industries.

What are the ways to prevent rust of Blind Rivets

1. Plating

Plating the blind rivet, this method is to put the rivet into the metal solution, and then use the current to apply a layer of metal to the surface, which has many effects on this layer of metal.

2. Mechanical coating

The mechanical plating of the blind rivet is to allow the metal particles to cold welded the blind rivets to ensure that the surface of the blind rivet has some effects. The mechanical coating and electroplating are basically the same, but the methods are different. The results can be said to be the same.

3. Hot treatment

For thermal treatment of blind rivet surfaces, some pop rivet surfaces are relatively hard, so you can heat the pop rivets to ensure that the pop rivet has sufficient hardness. This is why heat treatment is performed.

4. Surface passivation

Passing the blind rivet surface has two main functions. One is to enhance the hardness of the rivets, and the other is to greatly reduce the oxidation level of the blind rivets.