Material

| Body | Aluminum ( 5052) | Steel | Stainless Steel ● | |

| Finish | Polished | Zinc Plated | Polished | |

| Mandrel | Steel | Stainless Steel | Steel | Stainless Steel ● |

| Finish | Zinc Plated | Polished | Zinc Plated | Polished |

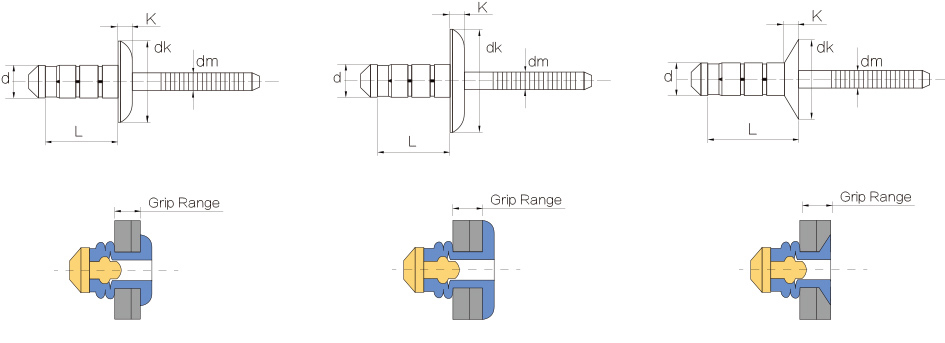

| Head Type | Dome, CSK, Large Flange | |||

Specification

| Size | Drill | Part No. | M | Grip Range | B | K | E | Shear | Tensile |

| max | max | max | max | KN | KN | ||||

| 3.2 (1/8" ) |

|

BBS11-00414 | 14.5 | 1.0-7.0 | 7.3 | 1.1 | 2.2 | 1.7 | 2.2 |

| 4.0 (5/32" ) |

|

BBS11-00516 | 16.0 | 2.0-8.0 | 8.2 | 1.5 | 2.8 | 2.7 | 3.4 |

| 4.8 (3/16" ) |

|

BBS11-00618 | 17.0 | 1.5-9.0 | 10.0 | 1.6 | 3.1 | 4.5 | 5.0 |

Application

Multi grip rivet is a kind of rivet used for single side riveting, and it is also a new fastener for blind riveting. In riveting, it uses its own deformation or interference connection to closely connect two or more riveted parts. The multi grip blind rivet is a kind of high-strength fastener with broken core, which is especially suitable for the riveting occasions where it is inconvenient to use ordinary rivets (which must be riveted from both sides). The materials of multi grip type blind rivets are generally divided into aluminum 5050/5052/5056/5154, steel, 304 stainless steel, etc.. Among which aluminum and stainless steel have strong corrosion resistance and steel has high strength.

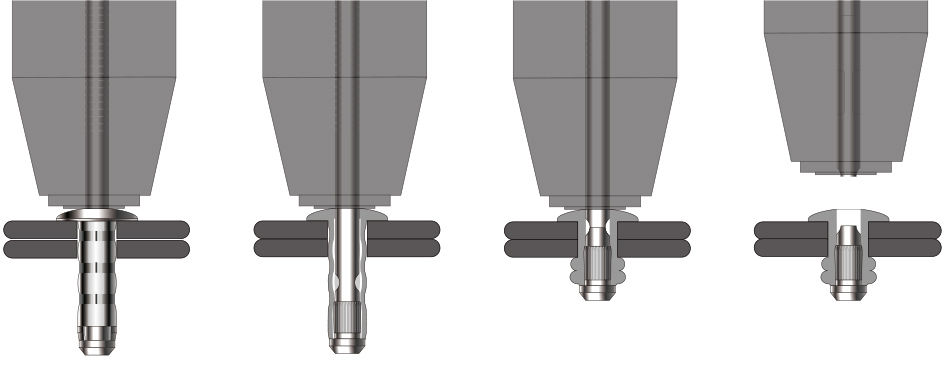

There are two types of Grip rivets: uni grip rivets and multi drum pop rivets. During riveting, the rivet mandrel pulls the end of the rivet body into a double drum rivet head to clamp the two riveted structural members and reduce the pressure and stress deformation on the surface of the structural members.The cost of multigrip type blind rivet is higher than that of ordinary blind rivet. After 304 stainless steel is used, the cost is higher. The advantages of stainless steel multi-grip rivets are as follows:

1.High tensile and shear resistance

2.High temperature resistance

3. It has sealed performance

4. Applied to thin sheet materials

5. Reduce the pressure of rivet on the workpiece to ensure that the workpiece is not easy to deform.

The 304 stainless steel multi grip pop rivets produced by Handan Wodecy Fastener perform perfectly in the application of refrigeration equipment. Our customers use 304 stainless steel multi grip rivets to fasten all sheet metal riveting parts in the production of equipment. This not only makes the riveting more tight, but also provides a very strong corrosion resistance for the use of refrigeration equipment under severe working conditions, which greatly extends the service life of the equipment and enhances the operating efficiency of the cold storage. Wodecy Fastener helps customers produce high-quality products.

What are the differences between 304 stainless steel pop rivets and 316 stainless steel pop rivets

The main difference is that the materials are different.

304 stainless steel, namely 06Cr19Ni10 and SUS304, in which 06Cr19Ni10 generally refers to production according to national standards, 304 generally refers to production according to ASTM standards, and SUS 304 refers to production according to Japanese standards. 304 material has high tensile strength and yield strength, corrosion resistance, high temperature resistance, good mechanical properties, and no rust, and is trusted by customers.

316 stainless steel, namely 0Cr17Ni12Mo2316, mainly reduces Cr content, increases Ni content and increases Mo2%~3%. Therefore, its corrosion resistance is stronger than 304, and it is suitable for use in chemical, seawater and other environments.