Material

| Body | Aluminum(5050 5052 5056) ● | Steel | Stainless Steel | ||||

| Finish | Polished, Painted | Zinc Plated | Polished | ||||

| Mandrel | Aluminum | Steel ● | Stainless Steel | Steel | Aluminum | Steel | Stainless Steel |

| Finish | Polished | Zinc Plated | Polished | Zinc Plated | Polished | Zinc Plated | Polished |

| Head Type | Dome, CSK, Large Flange | ||||||

Specification

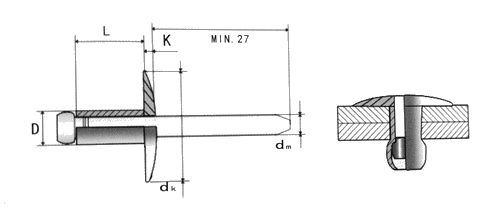

| D1 NOM. |

DRILL NO. &HOLE SIZE | ART. CODE | GRIP RANGE | L (MAX) | D NOM. |

K MAX |

P MIN. |

SHEAR LBS |

TENSILE LBS |

||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm |

#30 3.3-3.4 |

1-AS42LF | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | 0.375" 9.5 |

0.065" 1.65 |

1.06" 27 |

120 530N |

150 670N |

| 1-AS43LF | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| 1-AS44LF | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| 1-AS45LF | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| 1-AS46LF | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| 1-AS48LF | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| 1-AS410LF | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm |

#20 4.1-4.2 |

1-AS52LF | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.468" 12.0 |

0.075" 1.90 |

1.06" 27 |

190 850N |

230 1020N |

| 1-AS53LF | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| 1-AS54LF | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| 1-AS56LF | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| 1-AS58LF | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| 1-AS510LF | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| 3/16" 4.8mm |

#11 4.9-5.0 |

1-AS62LF | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.625" 16.0 |

0.092" 2.33 |

1.06" 27 |

260 1160N |

320 1430N |

| 1-AS63LF | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| 1-AS64LF | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| 1-AS66LF | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| 1-AS68LF | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| 1-AS610LF | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| 1-AS612LF | 0.626-0.750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| 1-AS614LF | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| 1-AS616LF | 0.876-1.000 | 22.5-25.4 | 1.200 | 30.5 | |||||||

| 1-AS618LF | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

Application

Large flange type blind rivets, the diameter of this rivet head is significantly increased compared to ordinary blind rivets. When riveting with connectors, the rivet has a larger contact area, a stronger support surface, and can enhance the torque strength. The large flange head pop rivet can withstand higher radial tension.

Applicable industry: It is suitable for fastening soft, fragile surface materials and extra large drill holes. The large flange head blind rivet can protect soft materials.

Why are the blind rivet mandrel exposed and pulled out during the use of pop rivets?

In the process of using pop rivets, consumers often have problems with exposed and pulled out rivet cores, which are mainly caused by improper use. Now let's share some tips on using pop rivets.

1. Select the matching rivet nozzle according to the specification and model of the pop rivet.

2. The rivet gun shall be used under appropriate air pressure. It is generally recommended to use it under air pressure above 6kg/m2. If the air pressure is too low, the rivet core head may be slowly deformed and drawn out.

3. The material of riveted parts shall be consistent with that of rivet body.

4. Riveting holes are reasonable. Riveting holes are generally 0.1-0.2mm larger than the outer diameter of the rivet body

5. The three claws in the rivet nozzle shall be replaced timely after being worn.

By paying attention to the above directions, the problem of rivet core exposure and withdrawal can be avoided.